HARDCORE MAX

The Hardcore Max has same trigger travel adjustment as standard Hardcore. The Hardcore MAX has a separate trigger pressure adjustment located in the housing approx. 1⁄4” below the actual trigger. This adjustment is an actual bolt that takes a 5/64” allen wrench. When the bolt is flush with the housing, the trigger is at its lightest which is around 4-6 ounces. Turning the bolt into the housing will increase trigger pressure. Turning it all the way will increase trigger pressure to 20-25 ounces. You may adjust this pressure anywhere in between. IMPORTANT: if the bolt is screwed in more than two full turns past being flush with the housing, the jaw may not auto reset. If it does not auto reset simply pull back on the trigger to reset jaw.

HARDCORE

Focus your attention on the set screw located on the trigger (directly under the jaw). Use a 1/16th allen wrench to make your adjustments. To decrease trigger travel, turn the set screw clockwise which will turn the set screw into the trigger. To increase trigger travel, turn the set screw counter clockwise which will move the set screw out of the trigger. Make sure and only move the set screw ¼ turn at a time and test the travel on something other than your bow (old bowstring, rope, etc).

EDGE RELEASES

Focus your attention on the set screw located on the trigger (you may have to pull the trigger down to see it). Use a 1/16th allen wrench to make your adjustments. To decrease trigger travel, turn the set screw counter clockwise which will bring the set screw out of the trigger. To increase trigger travel, turn the set screw clockwise which will move the set screw into the trigger. Make sure and only move the set screw ¼ turn at a time and test the travel on something other than your bow (old bowstring, rope, etc).

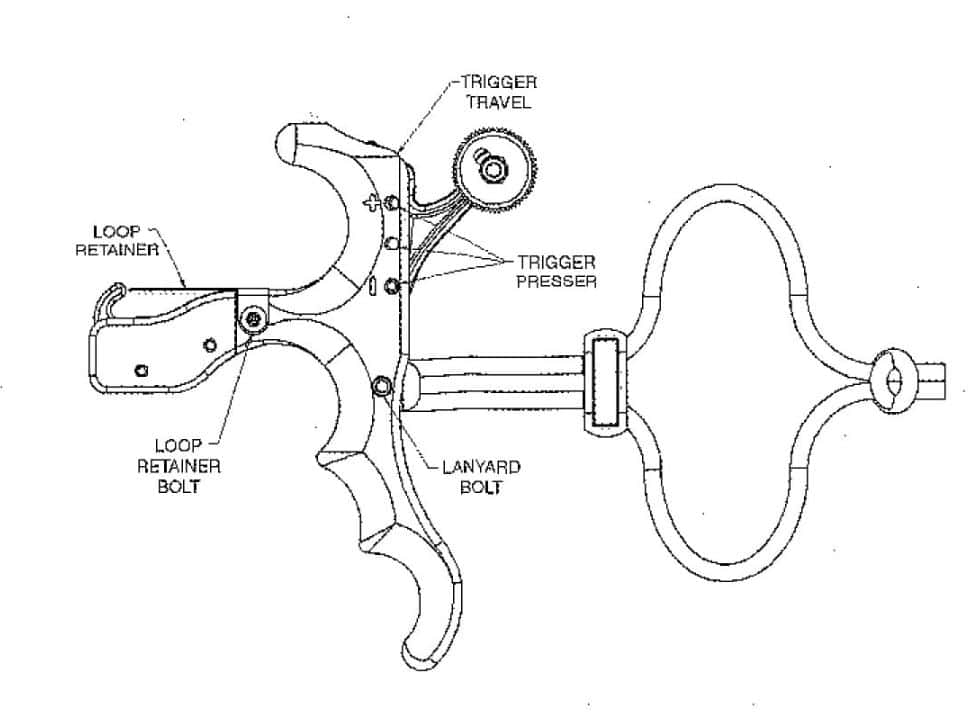

360 RELEASES

Underneath the trigger in the slot of the body you will see a nickel plated round part. While looking at this part, turn the head of the release. What you are trying to see on the part is a set screw. This set screw is 1/16th in size. Once you locate the set screw on the nickel plated part, go ahead and un-loosen the set screw by turning it counter clockwise only 1/4 turn of the allen wrench. This is important: make sure you leave the allen wrench in the set screw — if you want more travel (not as sensitive), turn the head of the release counter clockwise (have the head pointed at you). Try only turning the head of the release ¼ turn at a time (remember, the allen wrench still must be in the set screw). After you have turned the head the 1/4 turn, then tighten the set screw back up on the silver part. If you want the trigger to have less travel, you would have turned the head clockwise.

Trigger tension adjustment:

Take your release in your hand with the head pointed away from you. Turn the tension dial to the right or clockwise to decrease trigger tension. Turn the tension dial to the left or counter clockwise to increase the trigger tension. THIS DIAL DOES NOT ADJUST TRIGGER TRAVEL BUT TRIGGER PRESSURE ONLY.

HURRICANE, TEAM REALTREE, MOSSY OAK

Locate the set screw on the trigger. Using a 1/16th allen wrench, turning the set screw out or counter clockwise will decrease trigger travel. Turning the set screw into the trigger or clockwise will increase trigger travel. Make sure and move the set screw only ¼ turns at a time.

X-CALIPER, PATRIOT, SUREFIRE, X-CALIPER GLOVE

The X-Caliper has a 1/16th set screw located on the trigger. If you want less travel, rotate the set screw clockwise. If you want more travel, rotate the set screw counter clockwise. Make sure and move the set screw only ¼ turns at a time.

EDGE 4 FINGER, 3D HUNTER & STALKER 3 FINGER

There is a round nickel plated knob on the bottom of the handle (under the Tru-Fire logo). STEP 1) While turning the head of the release, look at the side of the knob and you will see a set screw ( when you turn the head, this knob should rotate). STEP 2) Put a 1/16″ allen wrench in the set screw and unloosen only ¼ turn. STEP 3) Keeping the

allen wrench in the set screw, turn the head of the release clockwise (HAVE HEAD OF RELEASE POINTING AT YOU) for less travel or counter clockwise for more trigger travel. IMPORTANT: Remember, clockwise of the head is less travel, counter clockwise is more travel. STEP 4) We suggest that you only move the head 1/8 turn at a time for adjustment. STEP 5) You should then tighten up the set screw and test the release. The set screw that is located on the handle, (near the neck of the handle) is there if you want to lock the head from rotating. You may want to use this feature if you are using a string loop. Do not over-tighten this set screw.

Stalker 3 Finger “push / pull” instructions: On the back of the handle are two holes labeled “push” and “pull”. When the screw is in the push hole, this means the trigger can only be fired by pushing the trigger. When the screw is in the pull hole, the trigger can only be fired by pulling the trigger. IMPORTANT: going from push to pull or pull to push will require you to have to re-adjust the trigger travel.

BULLDOG

Locate the set screw on the trigger. Using a 1/16th allen wrench, turning the set screw out or counter clockwise will decrease trigger travel. Turning the set screw into the trigger or clockwise will increase trigger travel. Make sure and move the set screw only ¼ turns at a time.

JUDGE RELEASES

Trigger travel adjustment: Locate the adjustment screw located underneath the trigger nearest the head by pulling back the trigger. Take 1/16th allen wrench and place allen wrench into the set screw and turn to the right or clockwise to increase trigger travel or to the left or counter clockwise to decrease trigger travel. CAUTION: this is a very sensitive adjustment, one complete turn of the allen wrench can take the release from full travel to not being able to hold the string.

Trigger Tension: Take the release in your hand, head pointed away from you, with one hand hold the rubber tubing and with the other turn the tension dial to the right or clockwise to increase trigger tension. Turn the tension dial to the left or counter clockwise to decrease the trigger tension.